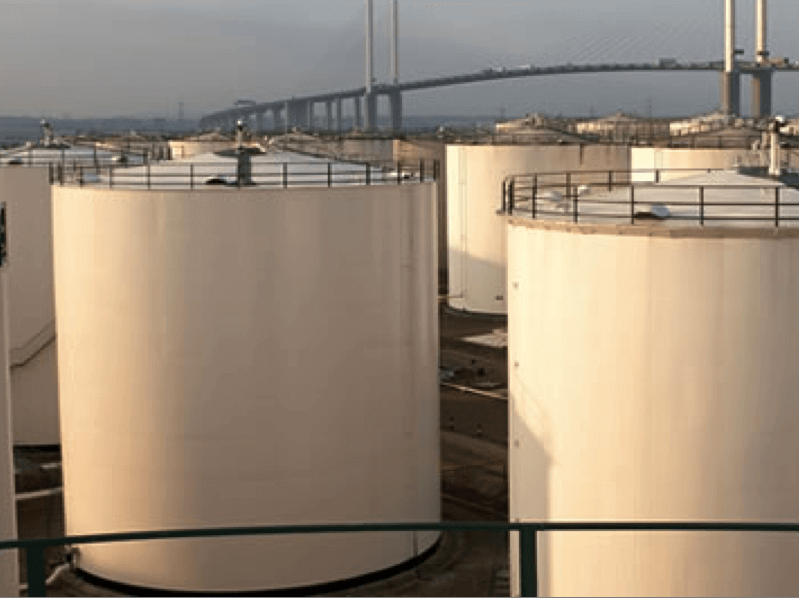

Purchase Tank Mixing agitators in Georgetown

Mixing agitators can be located in several markets, including the food industry, dairy products industry, starch, fertilizer industry, beverage industry, pharmaceutical industry, bio-based, cosmetic, and (petro) chemical industry, hydrometallurgical industry and allied markets.

The type of phase to be blended will certainly establish the option of mixing agitator This could be fluid just, fluid and gas, fluid and strong, or fluid with both solids and gas. The type of phase and mass of the mass establish the form of the agitator. It may also be called a mixer, kneader or dough mixer depending upon its feature. Mixing agitators for fluids can be put in different settings: up and down, flat, or, much less often, at the bottom of the tank.

We dont only offer Tank Mixing agitators in Georgetown, but also in Brooklyn, Parkville, Prospect Heights, Adelphi, Greenwood

What is the purpose of a Tank Mixing agitators

The motion of the heterogeneous phase (liquid-solid phase) is what creates agitation. This is attained by the rotation of an impeller in mechanical mixing agitators. It is possible for the mass to be comprised of several materials. The procedure’s objective is to blend it or enhance the efficiency of a response via a better get in touch with in between reactants. Agitation can also be utilized for warmth transfer and to keep fragments put on hold.

Jongia has actually produced this website to aid you find the best mixer for you. Dive to XXX for a low-priced, fast support rate on a tiny or mobile mixer. To get a comprehensive quote, please fill in the info listed below under the XXXXXX section.

We have a large range of mixing agitators thanks to our experience in chemical, food, dairy products and bio-based markets. Our commercial mixers are suitable for any type of application and customized mixing demands. Check out our line of mixing agitators.

Products

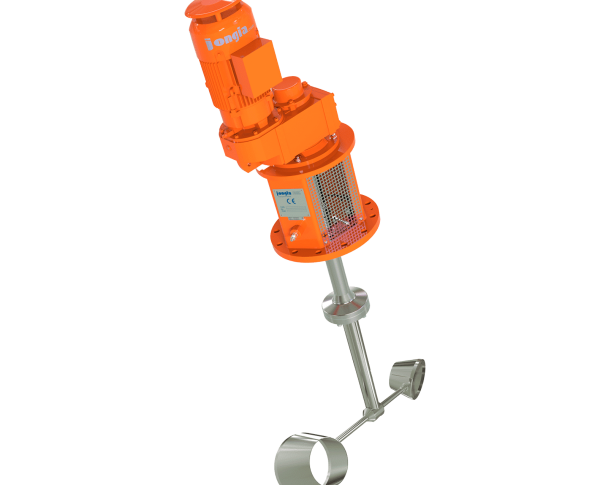

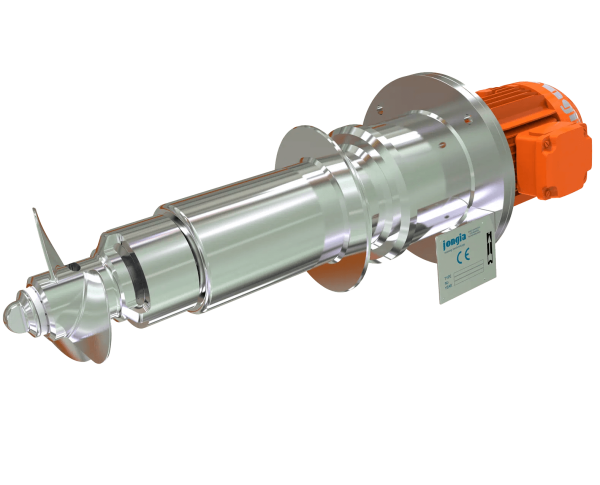

Jongia has a comprehensive range of stirring and mixing equipment and systems. We ensure the best possible solution for the given process, choosing from our wide range of mixers and agitators. We offer top, side and bottom entry, special designs like magnetic mixers, as well as dynamic and static in-line mixers and powder dissolving installations.

Impellers of a mixing agitator.

Mixing agitator is comprised of a drive gadget (motor and equipment reducer), belts …),, a leading system for the shaft (lantern with bearings), and impellers.

When operating conditions are high pressure or heats, the agitator ought to be fitted with a sealing system that keeps the tank’s inside from being harmed by the shaft.

A bearing at the bottom of the tank can assist the shaft if it is longer than 10m.

Several agitation impellers are utilized to upset fluid. The form of the impeller will certainly establish just how much power it can create.

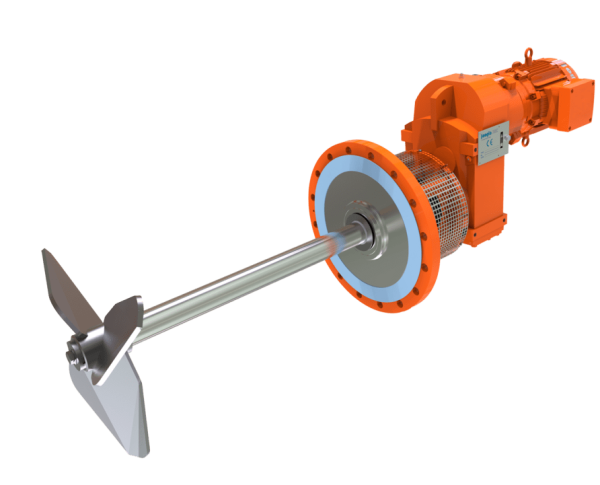

Propellers (marine and hydrofoil), have an inlet/outlet that is on an axial direction, preferably down. They are identified by a nice pumping flow and reduced power consumption, reduced shear magnitude, as well as reduced disturbance. An impeller, a blades creating a drawing pressure and which belongs to a pump, is an impeller

Turbines (flat or pitched blades) whose inlet flow is axial yet the outlet flow is round will certainly create shearing and disturbance. They require around 20 times a lot more power than propellers for the very same diameter and the very same rotation speed.

We have a large range of mixing agitators thanks to our experience in chemical, food, dairy products and bio-based markets. Our commercial mixers are suitable for any type of application and customized mixing demands. Check out our line of mixing agitators.

Impellers of a mixing agitator.

For mixing high thickness items like grease lubricants and adhesives, agitators with impellers that are a lot more effective or have double impellers may serve. Multi-agitator mixers have multiple independent agitators with adaptable controls that allow them to swiftly switch equipments to accommodate altering items. Multi-agitator mixers are terrific for companies that are concentrated on brief projects or fast transition.

When operating conditions are high pressure or heats, the agitator ought to be fitted with a sealing system that keeps the tank’s inside from being harmed by the shaft.

A bearing at the bottom of the tank can assist the shaft if it is longer than 10m.

Several agitation impellers are utilized to upset fluid. The form of the impeller will certainly establish just how much power it can create.

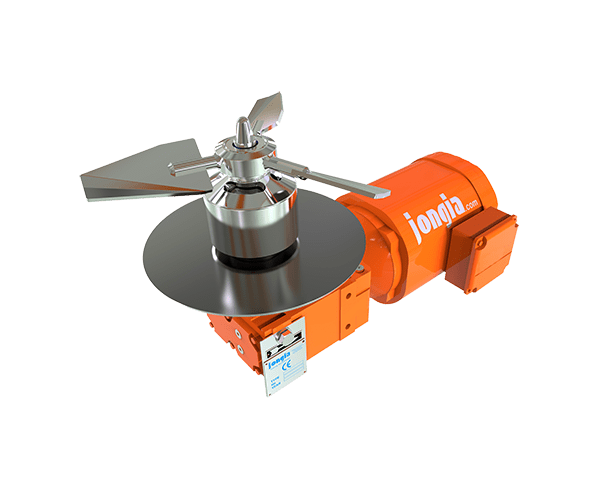

The forms of an impeller.

There are 4 sorts of impeller blades that make up an industrial agitator impeller:

— Flat blades;

— Bent blades

— Folded up or inline blades

— Spiral blades;