Purchase Blending agitator in Greenwood

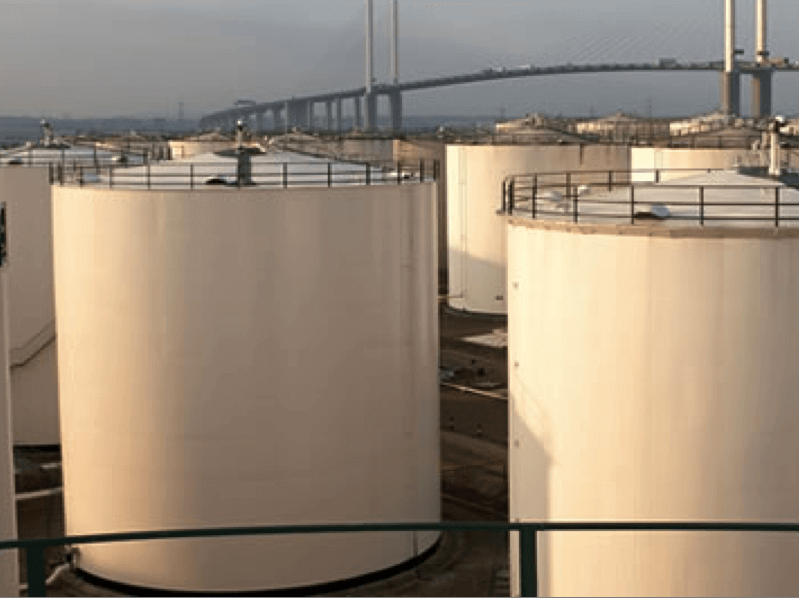

Blending agitators can be discovered in several industries, including the food market, milk market, starch, plant food market, drink market, pharmaceutical market, bio-based, aesthetic, and also (petro) chemical market, hydrometallurgical market and also allied industries.

The sort of stage to be blended will identify the choice of mixing agitator This could be liquid just, liquid and also gas, liquid and also strong, or liquid with both solids and also gas. The sort of stage and also bulk of the bulk identify the form of the agitator. It might additionally be called a mixer, kneader or dough mixer depending on its function. Blending agitators for liquids can be placed in numerous settings: vertically, flat, or, less frequently, at the end of the container.

We dont only offer Blending agitator in Greenwood, but also in Parkville, Prospect Heights, Adelphi, Brooklyn, Georgetown

What is the use of a Blending agitator

The motion of the heterogeneous stage (liquid-solid stage) is what triggers agitation. This is accomplished by the rotation of an impeller in mechanical mixing agitators. It is feasible for the bulk to be comprised of several materials. The procedure’s function is to blend it or improve the effectiveness of a response with a much better get in touch with between catalysts. Anxiety can additionally be utilized for warm transfer and also to keep fragments suspended.

Jongia has actually created this website to aid you discover the right mixer for you. Jump to XXX for a low-priced, fast assistance cost on a little or portable mixer. To obtain a thorough quote, please fill in the information below under the XXXXXX area.

We have a large range of mixing agitators thanks to our experience in chemical, food, milk and also bio-based industries. Our commercial mixers appropriate for any application and also custom-made mixing requirements. Check out our line of mixing agitators.

Products

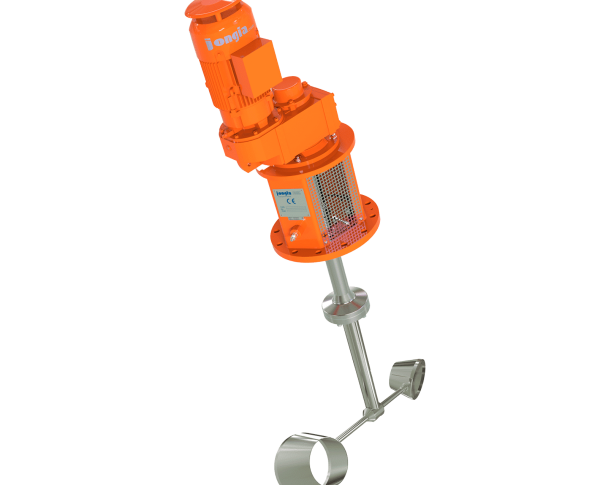

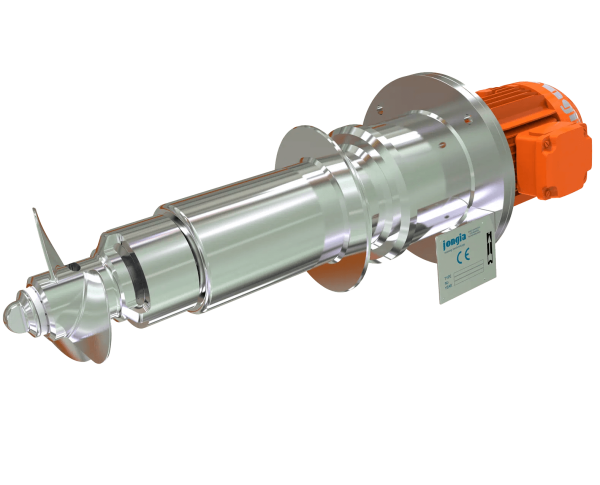

Jongia has a comprehensive range of stirring and mixing equipment and systems. We ensure the best possible solution for the given process, choosing from our wide range of mixers and agitators. We offer top, side and bottom entry, special designs like magnetic mixers, as well as dynamic and static in-line mixers and powder dissolving installations.

Impellers of a mixing agitator.

Mixing agitator is comprised of a drive tool (motor and also equipment reducer), belts …),, an assisting system for the shaft (lantern with bearings), and also impellers.

When operating conditions are high pressure or heats, the agitator ought to be fitted with a securing system that keeps the container’s inside from being damaged by the shaft.

A bearing at the end of the container can guide the shaft if it is longer than 10m.

Several agitation impellers are utilized to upset liquid. The form of the impeller will identify just how much power it can create.

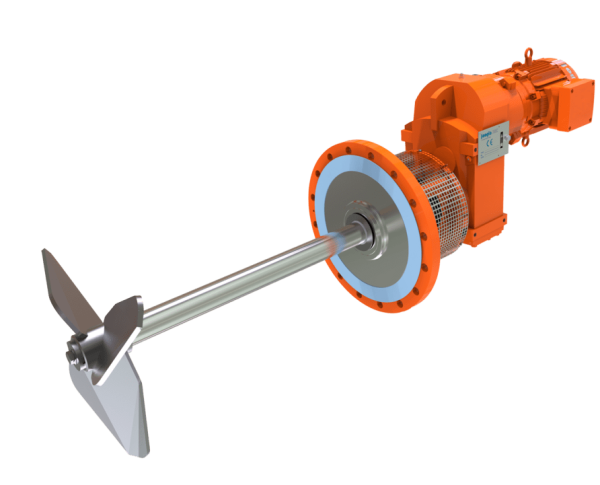

Propellers (marine and also hydrofoil), have an inlet/outlet that is on an axial instructions, ideally down. They are differentiated by a great pumping circulation and also low power consumption, low shear size, as well as low disturbance. An impeller, a blades creating a sucking pressure and also which becomes part of a pump, is an impeller

Generators (level or pitched blades) whose inlet circulation is axial however the electrical outlet circulation is circular will create shearing and also disturbance. They require around 20 times more power than propellers for the same size and also the same rotation rate.

We have a large range of mixing agitators thanks to our experience in chemical, food, milk and also bio-based industries. Our commercial mixers appropriate for any application and also custom-made mixing requirements. Check out our line of mixing agitators.

Impellers of a mixing agitator.

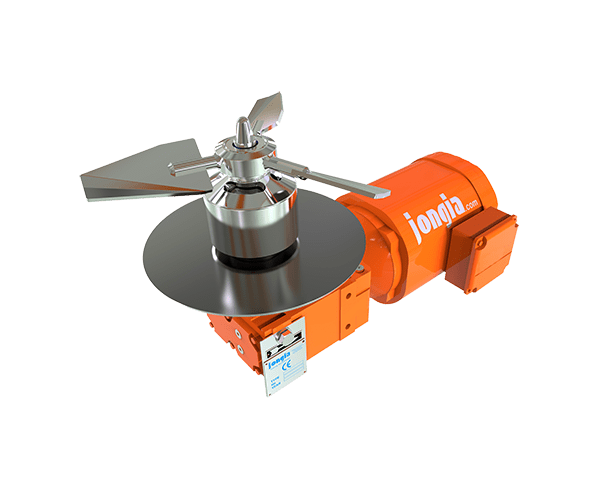

For mixing high thickness products like oil lubes and also adhesives, agitators with impellers that are more effective or have double impellers might be useful. Multi-agitator mixers have several independent agitators with versatile controls that enable them to promptly change gears to accommodate transforming products. Multi-agitator mixers are wonderful for firms who are concentrated on short projects or fast transition.

When operating conditions are high pressure or heats, the agitator ought to be fitted with a securing system that keeps the container’s inside from being damaged by the shaft.

A bearing at the end of the container can guide the shaft if it is longer than 10m.

Several agitation impellers are utilized to upset liquid. The form of the impeller will identify just how much power it can create.

The shapes of an impeller.

There are four types of impeller blades that comprise a commercial agitator impeller:

— Apartment blades;

— Rounded blades

— Folded or inline blades

— Spiral blades;